As a manufacturer and developer of Lead-Acid batteries and Lithium-Ion batteries, Triathlon® produces batteries for a wide range of industrial motive power applications, including electric forklifts and pallet trucks, mobile lifting platforms and cleaning machines. Decades of experience and technical expertise combined with state-of-the-art production facilities ensure the highest quality of motive power batteries. Triathlon's solid network of sales and service partners provide competent solutions and reliable onsite service.

TriCOM® Lead Acid Batteries

Triathlon Lead-Acid batteries utilize the highly sophisticated European tubular plate technology with flexible bolt-on inter-cell cable connectors. Triathlon tubular batteries are designed specifically for all motive power heavy duty applications and multi-shift operations.

Features:

- European tubular design with flexible, bolt-on inter-cell connectors

- Easy terminal cable and cell replacement using a torque wrench - no flame required

- Greater durability and flexibility on uneven flooring

- Improved safety with “built-in” shrouds

- QR Code Data Card attached to every battery for easy battery identification

- Spiral bound cable protectors keep the cables from getting cut or damaged

- Color coded positive and negative terminations for easily recognizable polarity

- Individual cell voltages can be taken without removal of any shrouds or exposure to lead

Tubular Flex AQ

- AQ = AQUAsave - Considerably reduced watering intervals (30-90 days) depending on charge profile

- Greatly reduces watering maintenance costs over the service life of the battery

- Available in standard US cell sizes: 90 Ah with 21.73” Height, 100 Ah with 24.68” Height, 125 Ah with 29.49” Height

- Also available in standard DIN and BS cells sizes

Tubular Flex EC

- EC = Enhanced Capacity - Experience longer run times with more available capacity in the standard cell sizes due to tubular plate technology

- Available in standard US cell sizes: 100 Ah with 21.73” Height, 140 Ah with 29.49” Height

- Standard specific gravities for long life

Tubular Flex Euro

- European standard DIN and BS batteries now easily available in North America

- DIN = German Industrial Standard, BS = British Standard

- Longer run times due to maximized battery capacity of European-designed lift truck compartment

- Also available in AQUAsave and Gel (Valve Regulated Lead Acid)

AQUAmatic Battery Watering System

The AQUAmatic water filling system provides quality and reliability - whether in traction batteries, in stationary installations, or electric commercial vehicles and cleaning machines. The core of the water refill system is the injector plug. The right system for each battery type is guaranteed to be correct due to a wide variety of choices.

The automatic filling system consists of mechanically operated water refill plugs with a float control made of acid-resistant plastic, a hose system made of transparent PVC, connectors and accessories.

System Features:

- Easy handling - can be installed quickly and easily

- Fill level - always exactly at the same level

- Functional reliability - caps are no longer opened by hand

- No risk of injury - since there is no contact with battery acid

- Cost savings - time it takes to refill batteries is considerably reduced

AQUAtank

AQUAmobil

AQUAcontrol

AQUApoint

Tubular Flex Aire System

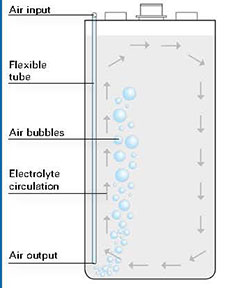

Batteries equipped with a Triathlon Tubular Flex Aire agitation system and the TriCOM charger prevent acid stratification by using air bubbles to mix the electrolyte throughout the charging process. Triathlon Tubular Flex Aire allows less overcharge, which reduces energy demand, minimizes water loss and reduces battery temperature increases.

- Reduces energy and water consumption – the charge factor goes from up to 1.20 to 1.05 -1.07

- Extends service life by reducing chemical stress and temperature increases during charge

- Enhances battery performance in opportunity charge applications when the gassing point is not reached on each charge

- Speeds up the charging process

icon Battery Guard 4.0 Battery Controller

The icon Battery Guard 4.0 records and collects all relevant data events between the lift truck, battery and charger. These recorded events are able to be retrieved into a computer through wireless communication via Bluetooth. Controlling the charging and discharging activity, as well as monitoring the battery temperatures and the electrolyte levels are important measures to ensure the maximum operating time of the vehicle fleet at all times.

System Features:

- Intelligent current measurement - by using an easily mountable current measuring head.

- Wireless communication via Bluetooth - the relevant operating data in the interaction between industrial truck, traction battery and charger can be recorded, stored and retrieved.

- High storage capacity - storage of more than 4.000 discharge and charge data events with date, time and duration.

- Status display - large status display with programmable status information.

- Digital display - customizable content display e.g. voltage, current, charge state, temperature, last charge, fault information.

- Robust housing - shock and vibration tested.

- Easy installation – no special tools required.

- Easy retrieval and processing of stored data: Readout through the wireless interface with Bluetooth, data transfer to a laptop / PC, or data transmission within the customer’s own network.

- Intelligent reporting - your saved data can be uploaded to the Internet. (your individual report is generated from this data)

- Info Battery Guard software - for individual programming of the controller and management of the data